The Tattle™ device uses a paddle mounted to a stainless steel rotating shaft. This shaft passes through an aluminum housing and is sealed with O-rings. The paddle forms a gate through which gas must pass in order to go through the indicator. On the outside, a flag is connected to the shaft and, on rotation of the paddle, is raised to indicate a change in the gate position. This raised flag, visible from a distance, has “tattled” that gas has passed through the device and a release has occurred.

The Tattle™ is a permanent solution and can be reset once triggered. If venting occurs and the gate is opened, the device is simply reset by rotating the shaft 90º to the original position. The flag’s movements are restricted to two positions by roll pins pressed into the housing and a spring clip holds the flag in place once the device has been triggered.

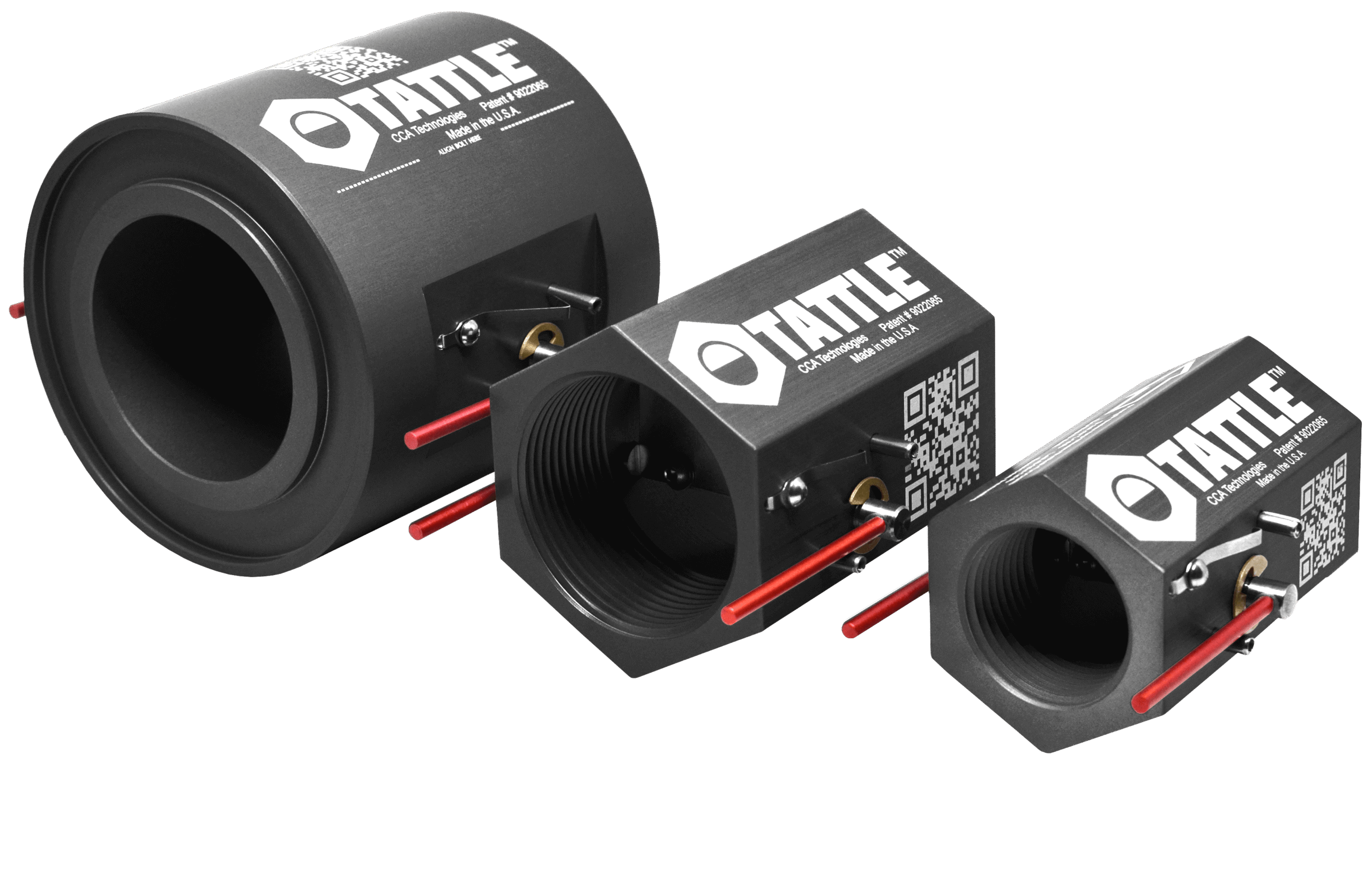

Because the Tattle™ is so reliable, the most interaction the system operator will have with it is during the initial installation. The Tattle™ comes in seven common sizes and is plumbed into the system using standard National Pipe Thread Taper (NPT) fittings for the 1″, 1¼”, and 1½” units or raised-face, gasket-sealed flanges (flanges not include) for the 2″, 2½”, 3″, and 4″ units.

The Tattle™ is the epitome of simplicity and, as long as the operator follows the guidelines for use, it will provide years of trouble-free service. With a single moving part and no complicated electronics that can produce erroneous readings, the device is virtually maintenance free. Once installed, the Tattle™ requires no special maintenance beyond a periodic inspection to ensure that there is no visible corrosion on the housing and that the flag and shaft rotate freely.

Even though the Tattle™ is installed outside the high pressure system it may still see some wear and tear. If for some reason, a problem does arise, the Tattle™ can be repaired with parts available online or replaced altogether at a fraction of the cost of other more complicated and expensive solutions.

Putting an isolation valve downstream of a PRV is not only a bad idea, but is indeed prohibited. However, the Tattle™ is an instrument and not an isolation valve. Even in the raised position the paddle does not fully obstruct the bore of the housing. In fact, the pressure drop across the Tattle™ closely matches that of a simple 90º pipe fitting and so should not raise any red flags.

The paddle material is designed to bend along the axle during a release if the axle becomes frozen in place for some reason and does not turn. So no matter what the case, the paddle will move parallel to flow in the event of a release and not impede the fluid flow.

Pressure Relief Valves are required to be ASME certified. But the Tattle™ is not a PRV and furthermore is not installed in the pressure-containing envelope of the system. The Tattle™ falls in the category of an instrument and it has been designed and tested to operate with a maximum allowable working pressure much greater than the design pressure of the relief vent system.

The Tattle™ Relief Vent Indicator is manufactured and designed to be installed in relief valve discharge termination piping and not within the closed-loop refrigeration circuit. With that in mind, the Tattle™ is best classified as an instrument. As such, the Tattle™ complies with ANSI/IIAR 2-2014 §16.1.7 which requires that "The pressure-containing envelope maximum allowable working pressure of instruments and visual liquid level indicators shall be equal to or greater than the design pressure of the system or subsystem in which they are installed."

In addition, the Tattle™ complies with ANSI/IIAR 2-2014 §5.7 in that all materials used in the construction of the Tattle™ are suitable for contact with ammonia and will not deteriorate in the presence of ammonia, lubricating oil, or a combination of both.

The Tattle™ is constructed of both a hard anodized aluminum body and stainless steel axle and paddle which are consistent with ANSI/IIAR 2-2014 §5.7.2.1 which requires all metallic materials to comply with ASME B31.5 or ASME B&PVC Section VIII Division 1.

Ready to implement smarter safety solutions in your facility? Whether you’re sourcing new equipment, requesting technical data, or exploring partnership opportunities, our team is here to help. Connect with CCA Technologies to discuss your application, get a quote, or locate a distributor near you.